Early March 2012:

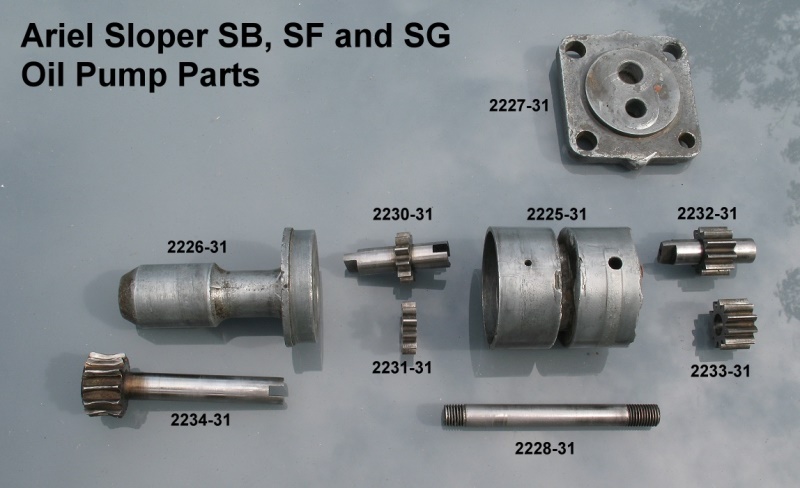

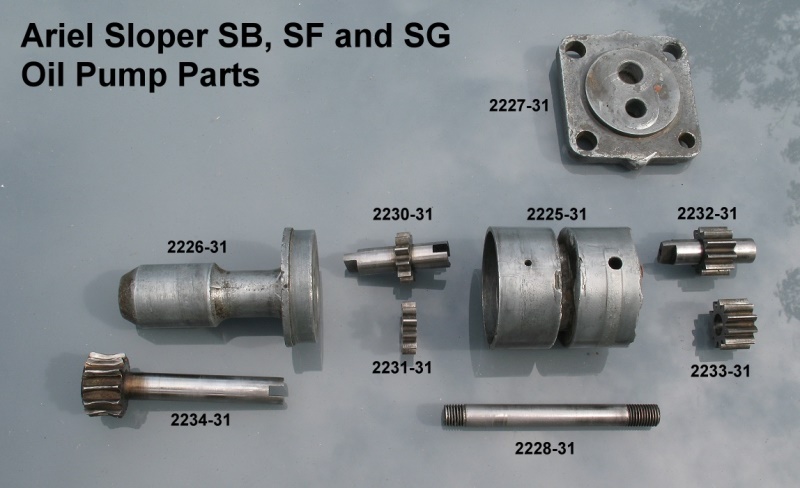

Started work on the engine at the beginning of the year but the oil pump has caused me no end of problems. I had been warned, by other Sloper owners, that this was the Achilles' Heel of the model but I didn't think it would take me quite so long to sort it out. To those not familiar with the model, the pump is made from Mazac / monkey / pot metal and, as a result, swells over time --- it then gets jammed in the crankcase and the steel gears within it also seize on their shafts. In severe cases, the driving dogs break.

Things weren't too bad on my pump. The internal steel gears were fine although a previous owner has emeryed the shafts a little so as to free them off in the pot metal. The bottom flange on the main central section had largely broken off and the top driving gear (2234-31) was badly worn...as was the worm gear on the timing side mainshaft.

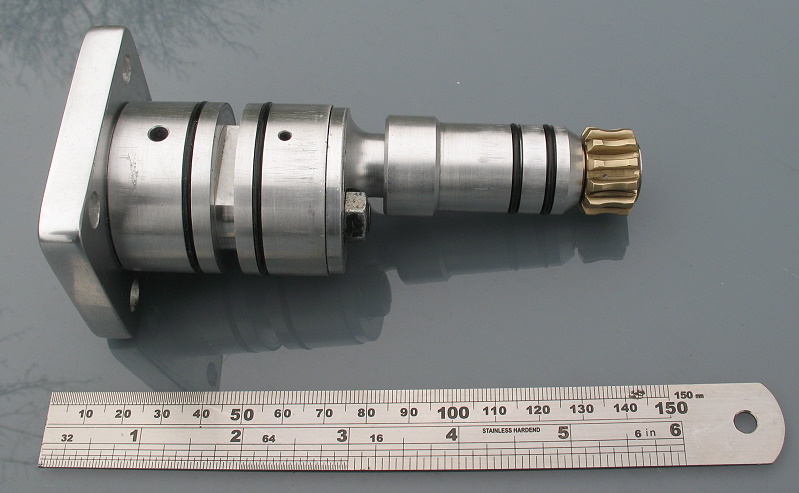

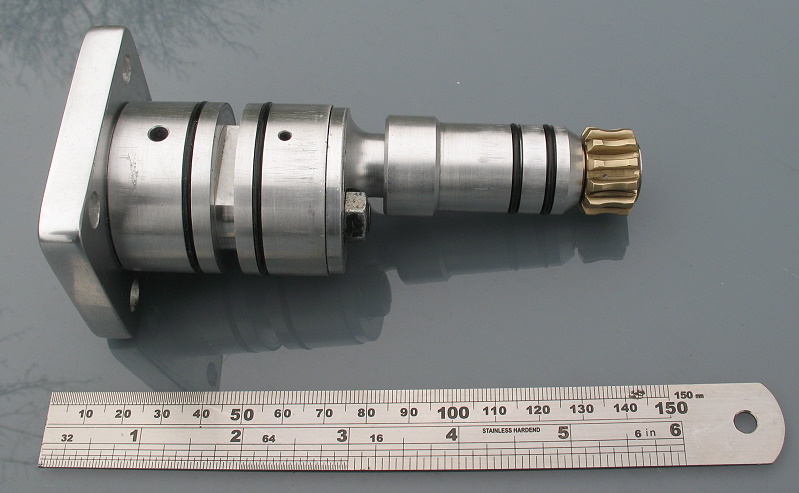

With a great deal of help and expertise from Paul Meredith and Clive Jones, my pump now looks like below. Parts have come from all over:

1. Internal steel gears are from the original pump above

2. Main central section (2234-31) and the top (2226-31) came from Clive....who I think got it from Kim Mortensen...who got it from ????... (I added the two O rings as per Paul's design)

3. The new top is for the Cammy version of the pump and therefore was too short for the Sloper. Extension piece with O rings was made by Paul

4. The new driving gear and shaft (22234-31) also came from Paul.

5. The new base (2227-31) made by me

Have obtained all the parts and then bolted it together, it wasn't exactly turning smoothly in either direction. It took copious amounts of engineer's blue, lots of man hours, etc to work out where it was binding and then relieving it. I certainly didn't want to remove too much metal and loose oil pressure, so it was a slow process to repeatedly dismantle and reassemble each time. And then there was the problem of adjusting the end float between "crankcase stop-and-driving gear" and "driving gear-and-extension piece bush" on the outside of the pump --- too detailed to try and explain here.

Does it work? Yes, at least on the bench. In practise? No idea and Paul would like me to stress that his bronze gear and shaft remain untested at this stage but I don't mind being the guinea pig --- I have every confidence in this pump; and that confidence comes from his engineering skills and the number of hours I've spent working on the bl**dy thing!

Now the pump is finished, it can be assembled into the crankcase half and then the flywheel mainshaft passed through its ball bearing in this crankcase half to mesh with it. i.e. you cannot remove this pump once the flywheels are installed and the crankcase halves are together....so it needs to be right first time.