Nev, would metal spraying be any better?nevhunter wrote:Any plating of crank parts will require heat treatment rather quickly for hydrogen embrittlement. If this is not done the shaft is likely to break . Nev

My Cammy Engine Blog

- paul.wirdnam

- Holder of a Silver Anorak

- Posts: 641

- Joined: Fri Apr 08, 2011 7:50 am

- Location: Okeford Fitzpaine, Dorset, UK

- Contact:

Re: My Cammy Engine Blog

Paul

- paul.wirdnam

- Holder of a Silver Anorak

- Posts: 641

- Joined: Fri Apr 08, 2011 7:50 am

- Location: Okeford Fitzpaine, Dorset, UK

- Contact:

- Steven.Carter

- Holder of a Platinum Anorak

- Posts: 4311

- Joined: Mon Feb 28, 2011 4:45 am

- Location: Eastleigh, Hampshire

- Contact:

Re: My Cammy Engine Blog

It's no wonder you like Watches!  .

.

- paul.wirdnam

- Holder of a Silver Anorak

- Posts: 641

- Joined: Fri Apr 08, 2011 7:50 am

- Location: Okeford Fitzpaine, Dorset, UK

- Contact:

-

nevhunter

- Holder of a Platinum Anorak

- Posts: 5052

- Joined: Tue May 10, 2011 9:42 am

- Location: Victoria.. Australia.

- Contact:

Re: My Cammy Engine Blog

Paul, metal spraying won't cause hydrogen embrittlement, but it may ruin the hardness and heat treatment specification. The heat treatment post plating is not difficult but it should be done without wasting too much time. Put it in hot oil for a few hours . I think about 160 degrees c. Check the figures. More time for thicker metal. Nev

- PeterW

- Holder of a Waxed Cotton Anorak

- Posts: 365

- Joined: Fri Oct 07, 2011 10:17 pm

- Location: Oxfordshire

- Contact:

Re: My Cammy Engine Blog

Fascinating photos - what a tremendous piece of engineering.

Think I'll stick to singles though!!

Think I'll stick to singles though!!

-

nevhunter

- Holder of a Platinum Anorak

- Posts: 5052

- Joined: Tue May 10, 2011 9:42 am

- Location: Victoria.. Australia.

- Contact:

Re: My Cammy Engine Blog

They were originally meant to drive to the gearbox through the centre gears I believe, but that didn't happen. The crank set up reminds me of the Scott. Certainly a bit of a challenge when they are old. No one would have imagined they would be running eighty years later. Edward Turner could have used a few more head bolts. A credit to anyone who perseveres and succeeds . BY the time the whole bike is done it is a monster job. Nev

- paul.wirdnam

- Holder of a Silver Anorak

- Posts: 641

- Joined: Fri Apr 08, 2011 7:50 am

- Location: Okeford Fitzpaine, Dorset, UK

- Contact:

Re: My Cammy Engine Blog

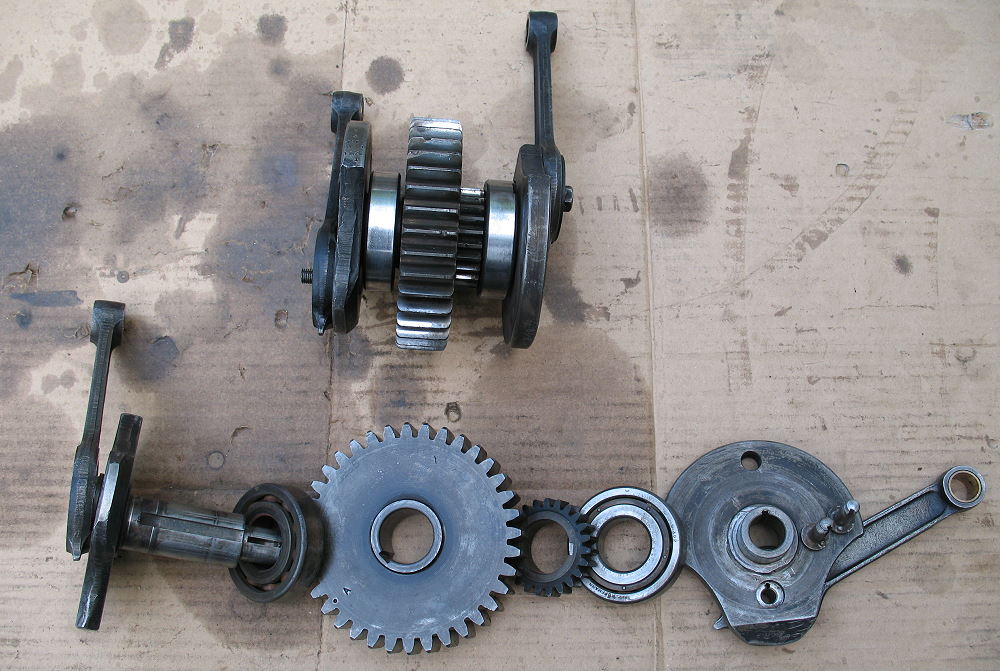

Today, I got the parts ready to ship off to A M Philpot (Hard Chrome) Ltd in Luton. They are going to prepare, metal spray, grind back to standard and fit the new inner races:

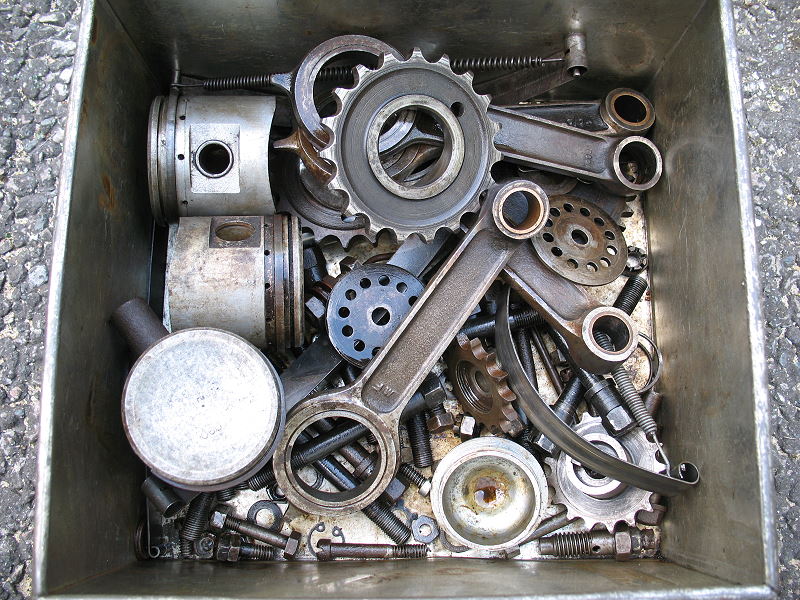

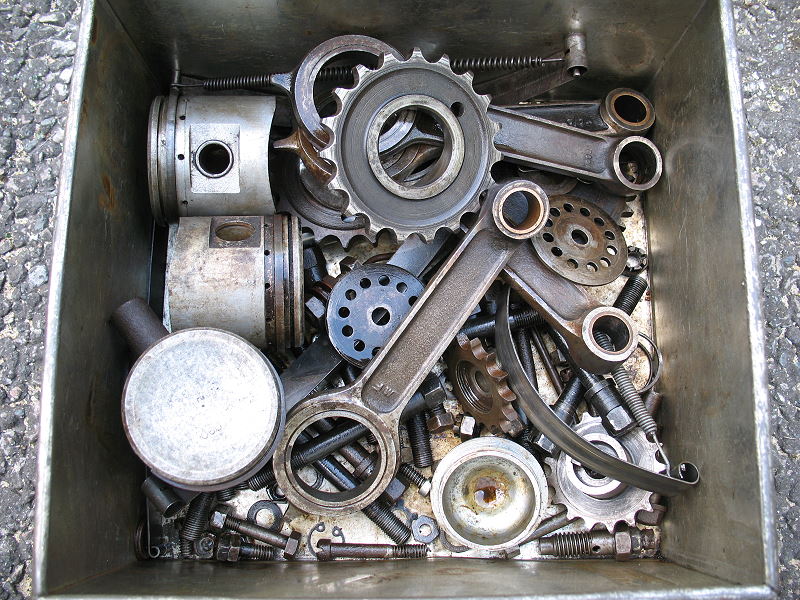

But before shipping on Monday, I thought I'd just check out a third Cammy engine that I have. This was an Old Bike Mart purchase about 13 years ago and came from somewhere near Dorchester. It had been partially dismantled and came with a biscuit tin full of head bolts, pistons, conrods, sprockets and other various small parts. I'd never given it much attention because I'd always considered it the worst of my two spare cammy engines i.e. only two conrod were installed etc

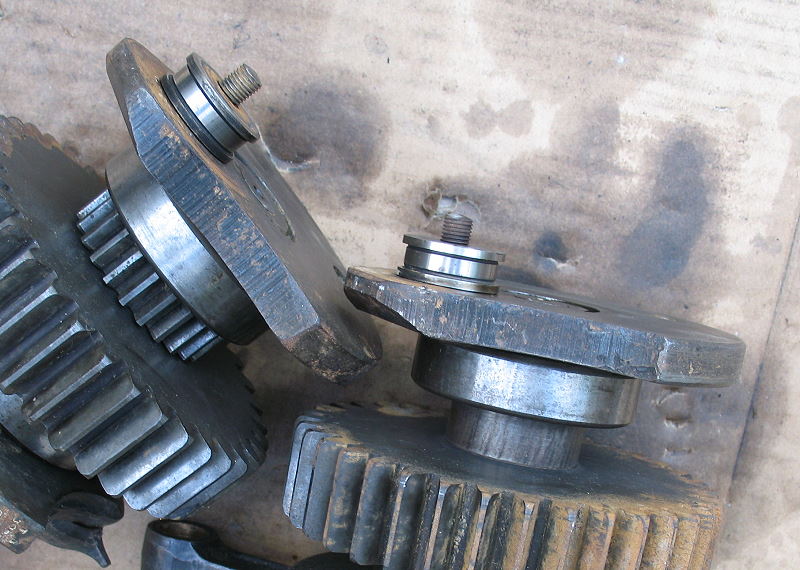

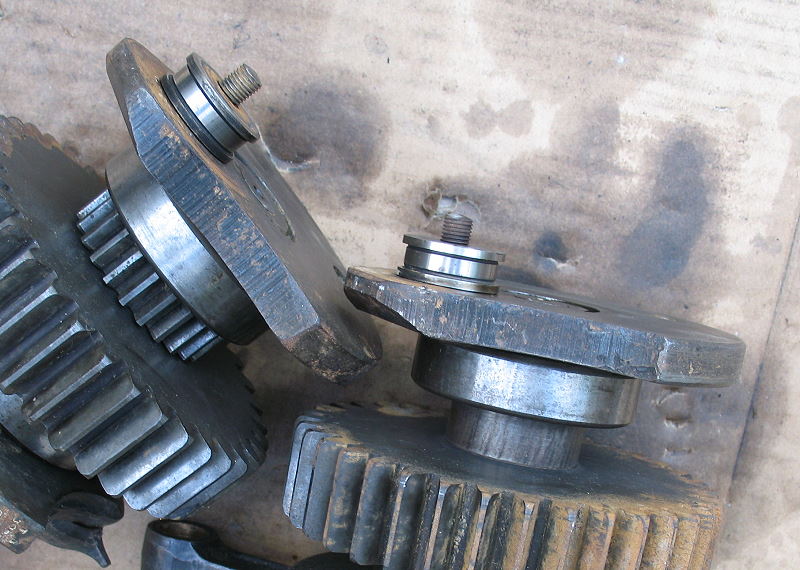

Oh, how wrong was I! After degreasing, the crank assemblies have a little surface rust; nothing that a wire brush wont remove. And the 2 inner races without the conrods look to be in very good condition and are tight on their crank pins. Numbers stamped on the inners are "W6918 HS". The two big ends of the fitted conrods seem to have no wear. Finally, the nuts holding the two crank assemblies together are perfect and still with their original Ariel punch marks to stop them coming undone.

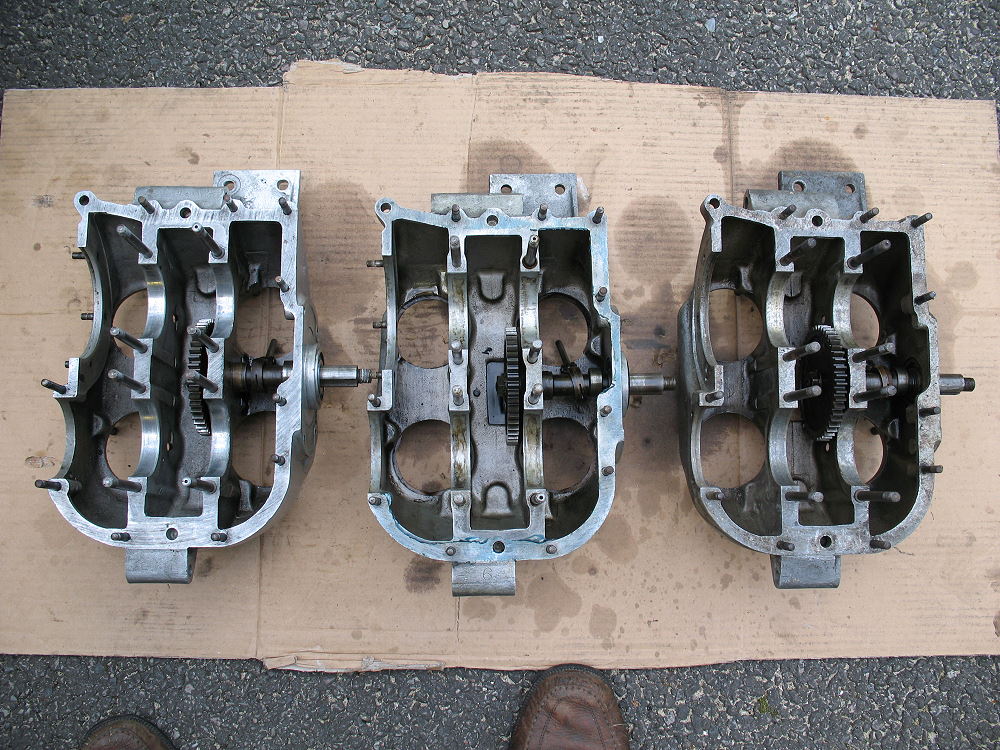

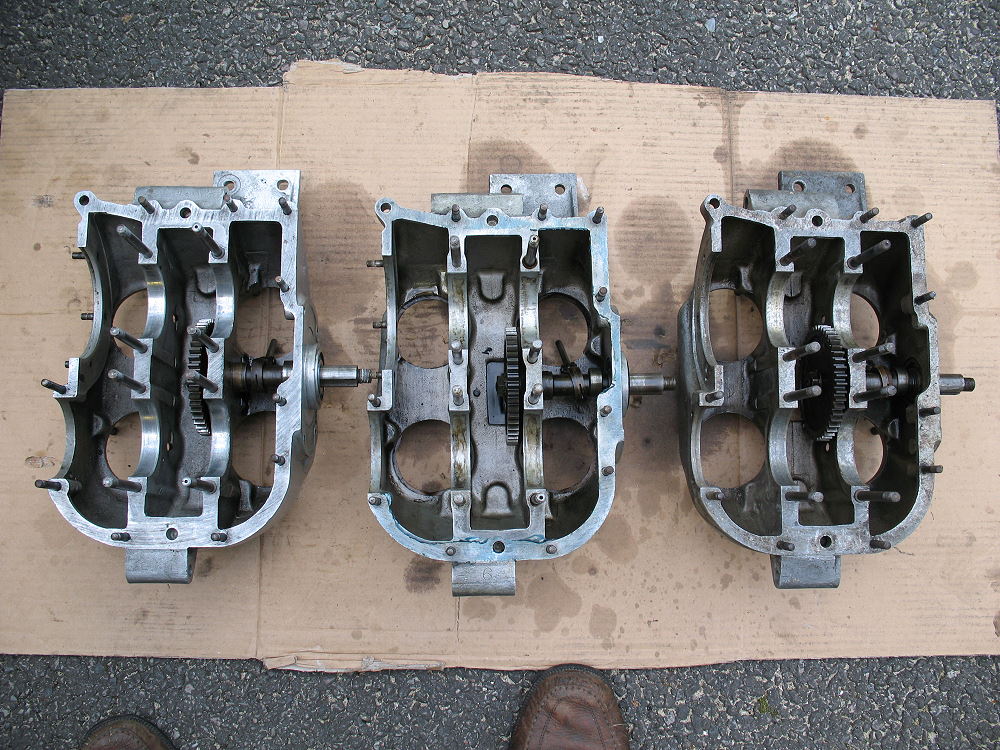

Took some photos of the three bottom crankcase halves and noticed that #1 (left) and #3 (right) have extra casting ledges on the inside which are absent from crankcase #2. I cannot work out what these ledges are for....

In summary, it looks like I need to check out these big ends on engine #3 a little more over the weekend...before deciding what to send off to the metal sprayer, if anything. It maybe that all four crank pins are OK...and maybe all four big ends as well.

Decisions, decisions!

But before shipping on Monday, I thought I'd just check out a third Cammy engine that I have. This was an Old Bike Mart purchase about 13 years ago and came from somewhere near Dorchester. It had been partially dismantled and came with a biscuit tin full of head bolts, pistons, conrods, sprockets and other various small parts. I'd never given it much attention because I'd always considered it the worst of my two spare cammy engines i.e. only two conrod were installed etc

Oh, how wrong was I! After degreasing, the crank assemblies have a little surface rust; nothing that a wire brush wont remove. And the 2 inner races without the conrods look to be in very good condition and are tight on their crank pins. Numbers stamped on the inners are "W6918 HS". The two big ends of the fitted conrods seem to have no wear. Finally, the nuts holding the two crank assemblies together are perfect and still with their original Ariel punch marks to stop them coming undone.

Took some photos of the three bottom crankcase halves and noticed that #1 (left) and #3 (right) have extra casting ledges on the inside which are absent from crankcase #2. I cannot work out what these ledges are for....

In summary, it looks like I need to check out these big ends on engine #3 a little more over the weekend...before deciding what to send off to the metal sprayer, if anything. It maybe that all four crank pins are OK...and maybe all four big ends as well.

Decisions, decisions!

Paul

-

nevhunter

- Holder of a Platinum Anorak

- Posts: 5052

- Joined: Tue May 10, 2011 9:42 am

- Location: Victoria.. Australia.

- Contact:

Re: My Cammy Engine Blog

You have some lovely 'family jewels" lying around, Paul. I'll just dig up another Cammy and check the bearings and find one that's probably able to be used. those lugs would be for setting up for machining the castings or perhaps a baffle that was never used. I wonder what the life of those motors was? Cantilever cranks are not the thing for high revs, and the Scott used them, but not their strong point as they suffer from crank breakage. The webs on the Cammy are much thicker. With all ball bearings the moisture and corrosion affect them if not used carefully. No short runs and regular oil changes. AGRI MU has a chemical in the oil to stop corrosion in tractors during lay -up in winter. I know some who use it in Henderson fours that take a long time to warm up for that reason. Your oil temp needs to hit about 90 degrees C to not have water condense in the oil. Nev

- paul.wirdnam

- Holder of a Silver Anorak

- Posts: 641

- Joined: Fri Apr 08, 2011 7:50 am

- Location: Okeford Fitzpaine, Dorset, UK

- Contact:

Re: My Cammy Engine Blog

Thanks Nev. There are no more Cammy engines hidden away, I promise. I've never had much of a problem with water condensation on the Cammy --- unlike my Silver Hawk which suffers quite badly from it.

As it happens, those nice looking inners races on these latest crank assemblies are not as tight as I first thought. They pulled off to reveal that they were stuck on with a film of congealed grease / dirt / rust, so I'll still be sending a set of cranks off on Monday for treatment. But I'm having a few problems shifting the assembly nuts on the latest cranks --- succeeded in breaking my CV 1" A/F socket last night .

.

As it happens, those nice looking inners races on these latest crank assemblies are not as tight as I first thought. They pulled off to reveal that they were stuck on with a film of congealed grease / dirt / rust, so I'll still be sending a set of cranks off on Monday for treatment. But I'm having a few problems shifting the assembly nuts on the latest cranks --- succeeded in breaking my CV 1" A/F socket last night

Paul

Who is online

Users browsing this forum: No registered users and 25 guests