In March of this year, I dug out my 1934 Cammy from the back of the garage; it had been SORNed for the last 5 years but I felt it was time to give it some TLC and start riding it again. I restored it in 1997 but sadly kept no records of what I actually did to the engine, gearbox etc.

Since March, I clocked up another 500-600 miles, making a total of about 9500 miles since 1997, and I've ironed out a few issues including:

New magneto bearings --- worn out

Shim out magneto end cover to get equal points gap on each of the two cam ring lobes

Rebuild PA Speedo --- it was coming part and stuck at 12

Better distributor cap and rotor --- heat was causing loss of spark through cap bakelite

New clutch plates --- one was missing!

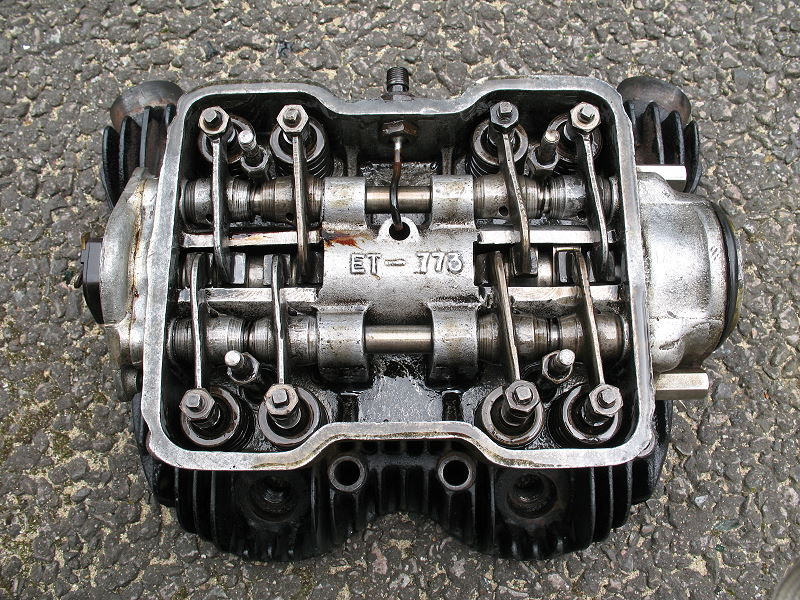

New camshaft main bearing

New camshaft drive chain

New magneto drive chain

Change of camshaft

Change of camshaft drive sprocket

Adjust valve timing

Now to the reason for this blog. The bike has been getting noisier and nosier....not from the exhaust but from the engine. There are two type of noise that I've been chasing:

1) this is a tinkle(!) type noise; not dissimilar to a tappet. It comes and goes and you can hear it at tickover and sometimes when driving relatively slowly.

2) this is more like a vibration/resonance that appears at 40mph and above.

The last couple of weeks, I've had the rockers, rocker spindles and camshaft apart several times, but having renewed chains, bearings, camshaft, nothing has made any difference to either of the two noises. Squirting oil with an oil can on the rockers, camshaft etc while engine is ticking over makes no difference to 1). Noise 2) is throttle related; as soon as you throttle back, the noise stops.

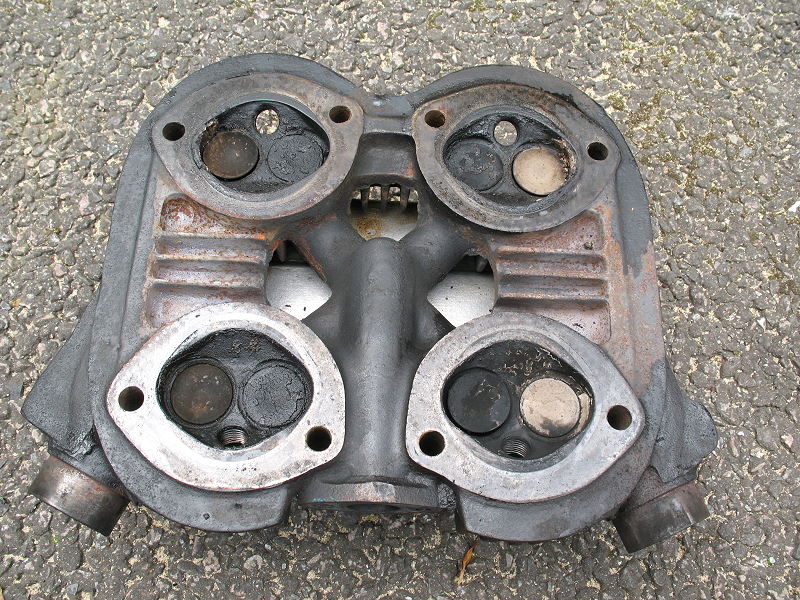

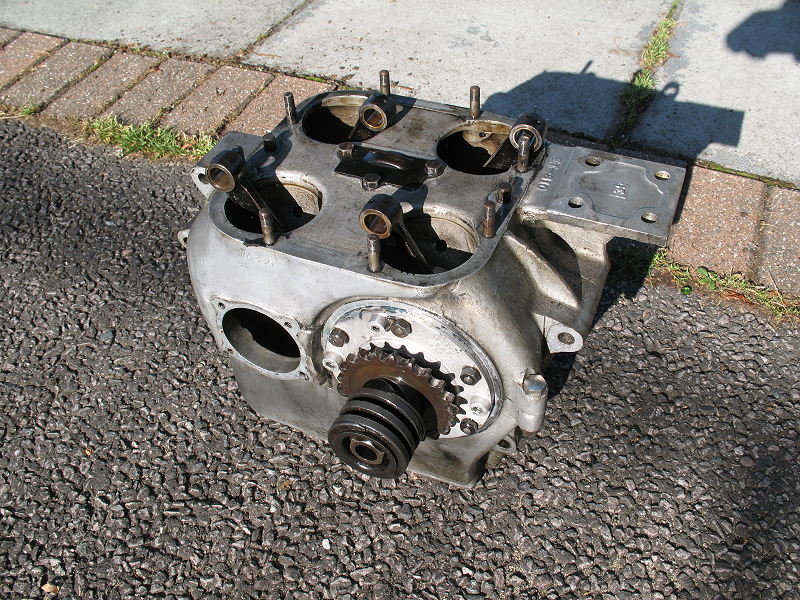

Today, I finally bit the bullet and decided to remove the head and barrel with the engine in the frame.

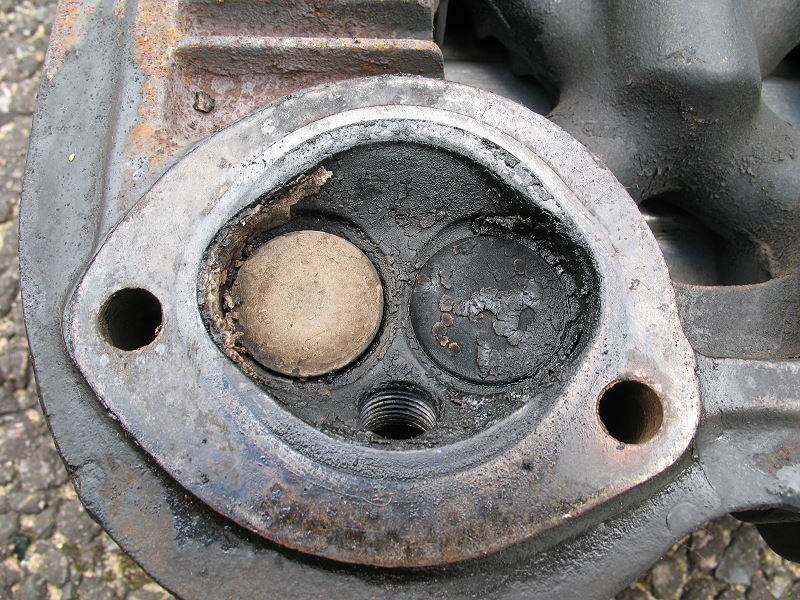

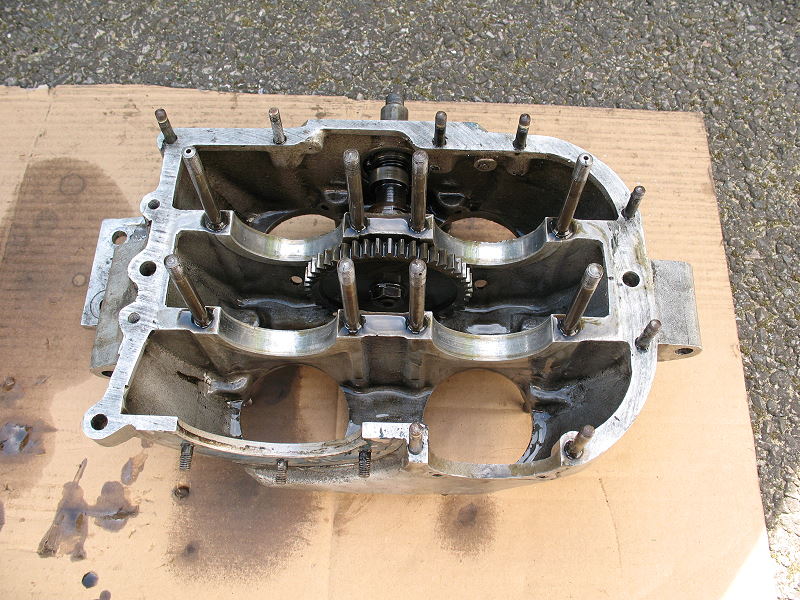

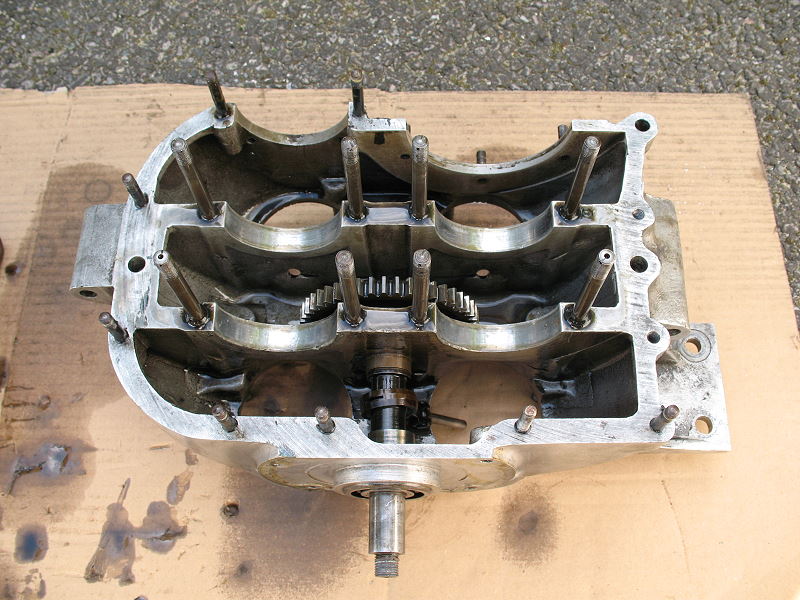

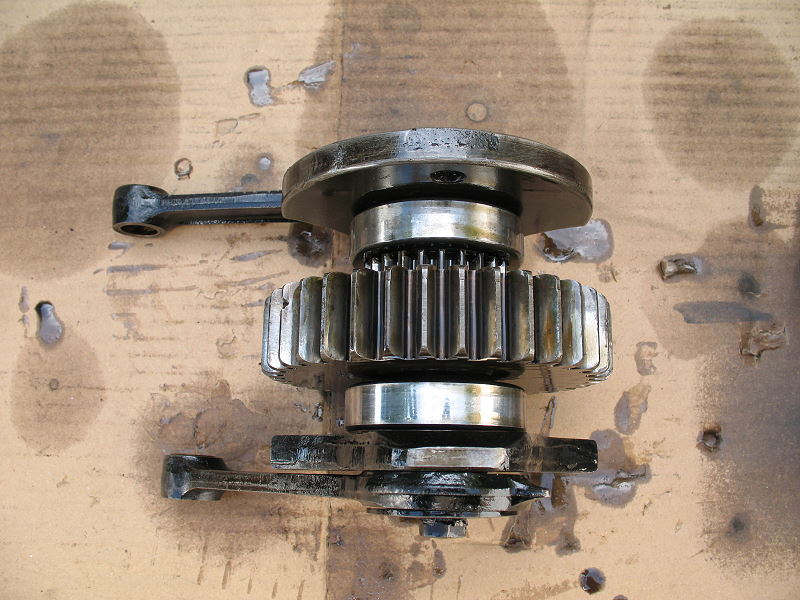

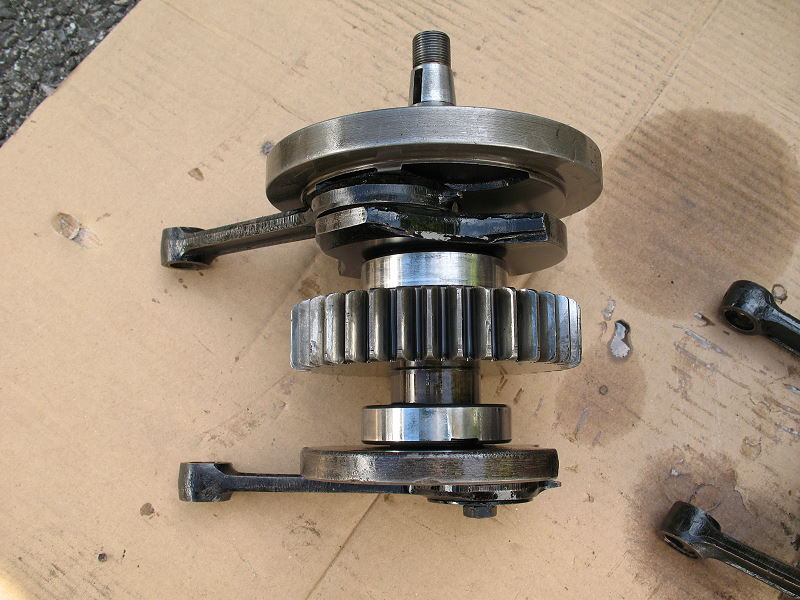

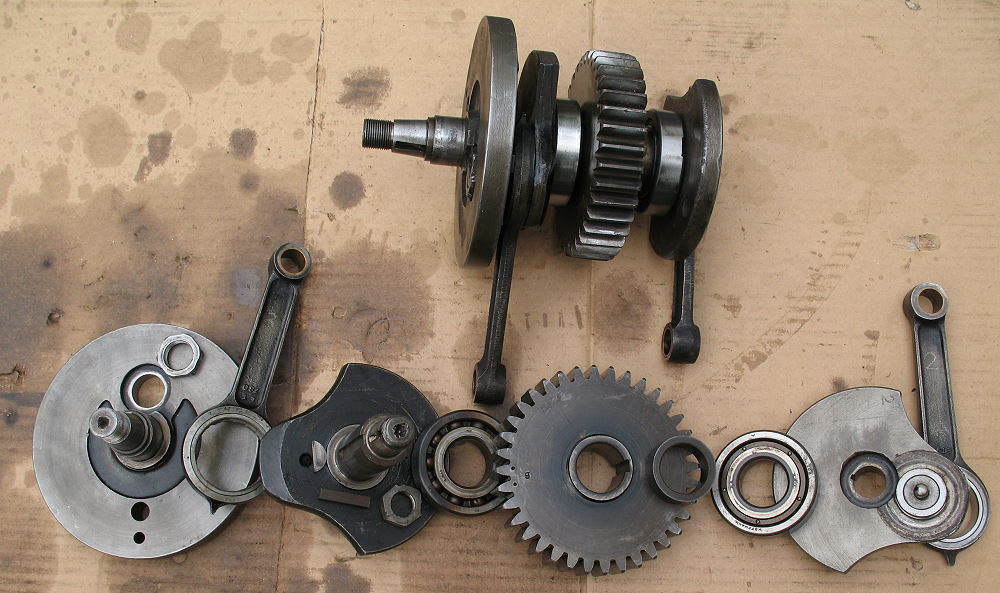

Big end on cylinder #1 : gone, easily detect up-and-down movement

Big end on cylinder #2 : slight up-and-down movement

Big end on cylinder #3 : gone, easily detect up-and-down movement

Big end on cylinder #4 : gone, this one has at least 1/16th up-and-down movement.

#4 looks really serious from what I can see through the crankcase. The Retaining Disc for Big End, plus bolt, plus nut are all loose...even though the bolt, nut and lock washer are tight together....so I'm not sure what's going on there until I split the crankcases.

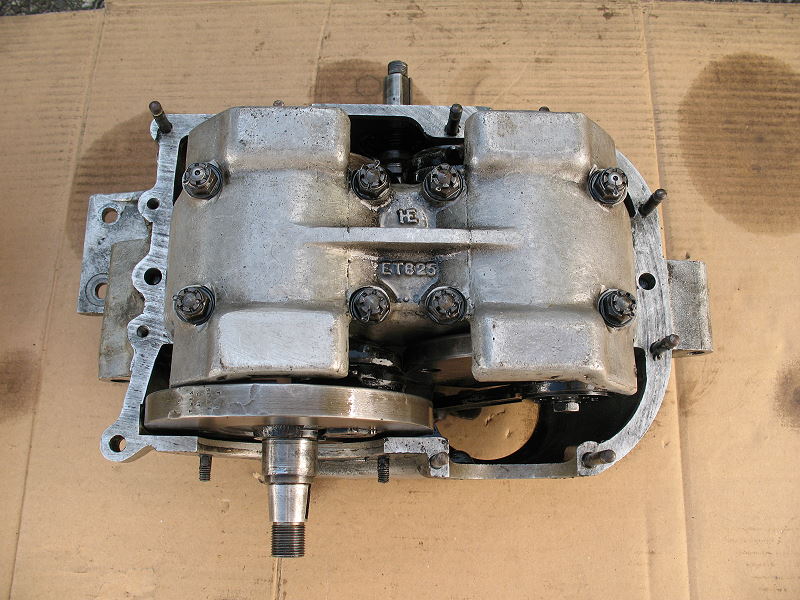

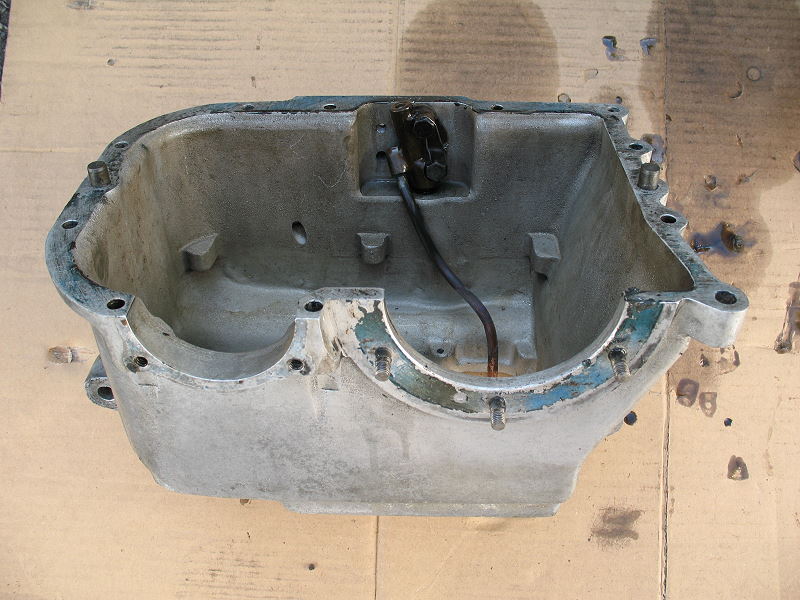

I'm glad I did this. Only last weekend I was riding the 4F in a rally, sometimes relatively fast. #4 looks as though something is about the break. Photos to follow once I've split the crankcase.